Mechanical manufacturing and processing technology: in-depth analysis and application

Mechanical manufacturing and processing technology is the cornerstone of modern industrial development, covering all aspects from design to production. This article will conduct an in-depth discussion from multiple aspects such as mechanical design foundation, processing technology planning, cutting principles and tools, mechanical processing equipment, manufacturing automation technology, quality inspection and control, materials and heat treatment, and advanced manufacturing technology.

1. Basics of mechanical design

Mechanical design is the starting point of mechanical manufacturing, and its goal is to determine the function, structure, shape, size and material of mechanical products. In the process of mechanical design, it is necessary to follow basic theories such as mechanical principles, material mechanics, and structural mechanics to ensure the stable and reliable performance of mechanical products. At the same time, modern mechanical design also needs to consider factors such as lightweight, environmental protection and energy saving to meet market demand and sustainable development requirements.

2. Processing technology planning

Processing technology planning is a key link in mechanical manufacturing, which involves the analysis, optimization and arrangement of the parts processing process. Reasonable processing technology planning can effectively improve production efficiency, reduce costs, and ensure product quality. When formulating the processing technology, it is necessary to consider factors such as the geometry of the parts, material properties, precision requirements, and the performance and characteristics of processing equipment such as machine tools, fixtures, and tools.

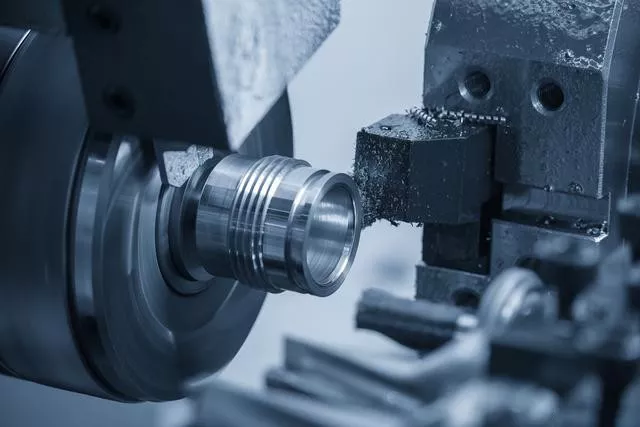

3. Cutting principle and tool

The cutting principle is the theoretical basis of mechanical processing. It studies the interaction between the tool and the workpiece and reveals the physical phenomena and laws in the cutting process. Understanding the cutting principle helps to select suitable tools, optimize cutting parameters and improve cutting efficiency. At the same time, as an important tool for mechanical processing, the type, material, geometric parameters, etc. of the tool will directly affect the processing quality and efficiency.

4. Mechanical processing equipment

Mechanical processing equipment is the material basis for realizing parts processing, including machine tools, fixtures, measuring instruments, etc. The performance, precision and reliability of these equipment directly affect the processing quality and efficiency. Therefore, in the process of mechanical manufacturing, it is necessary to select suitable processing equipment and perform regular maintenance and maintenance to ensure the normal operation of the equipment and extend its service life.

5. Manufacturing automation technology

Manufacturing automation technology is an important means to improve the efficiency and quality of mechanical manufacturing. By applying automated equipment and systems, functions such as automated control, online monitoring and fault warning of the processing process can be realized. This can not only reduce labor costs and improve production efficiency, but also reduce quality fluctuations and safety hazards caused by human factors.

6. Quality inspection and control

Quality inspection and control are key links to ensure the quality of mechanical manufacturing products. By adopting advanced detection technologies and means, such as three-coordinate measuring instruments, optical microscopes, etc., comprehensive and accurate inspection of parts during and after processing can be carried out. At the same time, by implementing quality control standards and processes, quality problems in the production process can be discovered and corrected in a timely manner to ensure the stability and reliability of product quality.

VII. Materials and heat treatment

Material selection and heat treatment processes have an important impact on the performance and service life of mechanical manufacturing products. Reasonable selection of materials and optimization of heat treatment processes can improve the hardness, toughness, wear resistance and other properties of parts, thereby improving the overall performance and service life of products. At the same time, attention should also be paid to the environmental protection and recyclability of materials to adapt to the development trend of green manufacturing.

VIII. Advanced manufacturing technology

With the continuous advancement and innovation of science and technology, advanced manufacturing technologies continue to emerge and be applied in the field of mechanical manufacturing. For example, digital manufacturing technology, additive manufacturing technology, intelligent manufacturing technology, etc. The application of these technologies can not only improve production efficiency and quality, but also realize the intelligence, greenness and flexibility of the manufacturing process.

In summary, mechanical manufacturing and processing technology involves many aspects, and various factors need to be considered comprehensively to ensure the smooth progress of the production process and the stability and reliability of product quality. With the continuous development of science and technology and the continuous changes in the market, mechanical manufacturing and processing technology will continue to innovate and improve, providing strong support for the sustainable development of modern industry.