Development and customization of Huawei mate20X stylus

Highlights of process difficulties:

1. Fusion of high-quality materials and innovative processes

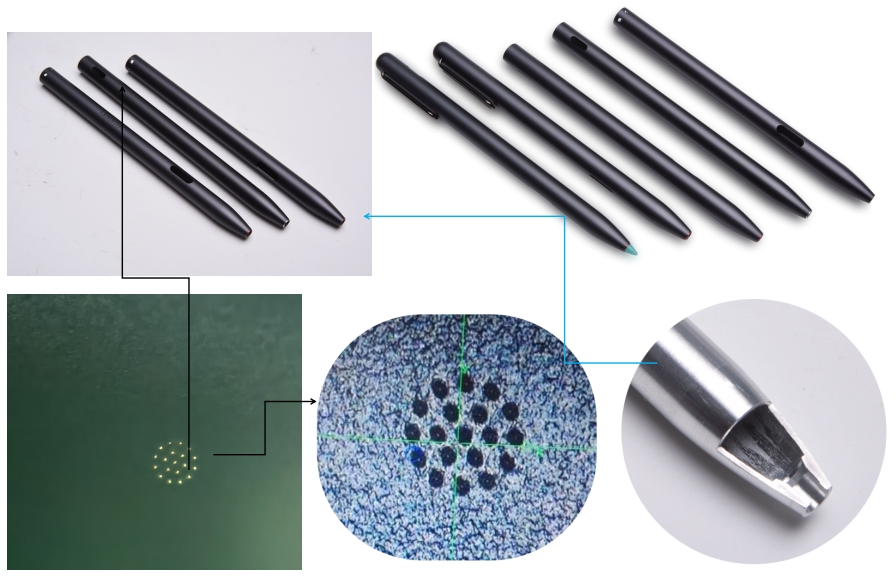

The pen barrel is made of high-quality aluminum alloy, which is strong and durable, and the good metal texture improves the overall quality. The pen tip adopts an innovative one-time molding process of internal and external integration, breaking through the limitations of traditional segmented processes. This process requires high-precision mold design and manufacturing, advanced processing equipment and strict process control to achieve a beautiful and smooth arc connection of the pen body, improving the appearance and comfort of holding.

2. High-precision one-piece molding

Achieving a tolerance control of 0.01MM inside the one-piece molding requires precision processing equipment, high-precision measuring instruments and a strict quality control system in mechanical processing. Accurately control the processing parameters to ensure that the size accuracy of each pen meets the standard, ensure writing smoothness and operability, and provide users with an ultimate writing experience.

3. Combination of primary anode and secondary high-light anode process

The ingenious combination of primary anode and secondary high-light anode process is a highlight of the process. In practical applications, due to the influence of the process on the material density, color difference problems are prone to occur. However, this problem was successfully overcome through this unique process combination.

The anodic process can form a uniform oxide film on the metal surface, which not only significantly improves the appearance of the pen and makes it more beautiful, but also greatly improves the corrosion resistance and prolongs the service life of the pen. The secondary high-light anodic process further enhances the color and gloss of the pen, making the pen look more beautiful. The red embellishment adds a luxurious texture to the pen, making it stand out among many writing tools.

To achieve this process, various parameters must be precisely controlled. From the voltage, current, time and other parameters of the anodic treatment to the process conditions of the secondary high-light anodic treatment, strict control is required. Only in this way can we ensure that the final delivered products meet the standards of high quality and high precision and meet the needs of users for high-quality writing tools.

4. Microporous light transmission and anti-corrosion filling process

The charging hole light transmission hole adopts a 0.5MM diameter 19 0.05MM microporous light transmission design, combined with a transparent high-temperature anti-corrosion filling process. This process requires high-precision microporous processing technology and strict filling process control. Microporous light transmission ensures the visibility of the charging status, and anti-corrosion filling prevents sweat and other foreign objects from penetrating and damaging internal components, extending the service life of the pen, reflecting the attention to user needs and product quality.

Technology highlights and difficulties:

1. Combination of high-quality materials and innovative processes: The pen holder is made of high-quality aluminum alloy, which is not only sturdy and durable, but also has a good texture. The pen tip is innovatively used for the first time with an internal and external one-time molding process, breaking through the shackles of the traditional metal pen segmentation process, so that the pen body arc connection is beautiful and smooth, which not only improves the appearance of the pen, but also increases the comfort of holding.

2. High-precision one-piece molding: Achieving a tolerance control of 0.01MM inside the one-piece molding is an extremely high process requirement. It ensures the fluency and operability of the pen when writing, bringing users an ultimate writing experience.

3. The combination of primary anode and secondary high-light anode process: not only overcomes the strict color difference requirements due to the process affecting the material density, but also the secondary anode process can still maintain the perfect color presentation, and the red embellishment makes the pen present a luxurious texture as a whole.

4. Microporous light transmission and anti-corrosion filling process: The charging hole adopts an innovative microporous light transmission design with 21 0.05MM apertures evenly distributed within a 0.5MM diameter range, combined with a transparent high-temperature anti-corrosion filling process. This unique process not only ensures the light transmission of the charging hole, making it convenient for users to check the charging status, but also effectively prevents sweat or foreign matter from penetrating and damaging internal components.

Previous: No More